Attention Michigan Structural Fabricators

Professional Engineer in Michigan – Structural & Mechanical Services Fabrication & Construction Projects

From major cities to rural hubs, our licensed engineers help Michigan fabricators, builders, and project managers eliminate risk, cut costs, and deliver safe, buildable steel designs.

Attention Michigan Structural Fabricators

Professional Engineering Services for Michigan

Fabrication & Construction Projects

From major cities to rural hubs, our licensed engineers help Michigan fabricators, builders, and project managers eliminate risk, cut costs, and deliver safe, buildable steel designs.

The Problem

Engineering Bottlenecks Cost Michigan Companies Time and Money. Projects stall when drawings aren’t constructible, shop crews can’t execute, or permits demand a PE stamp. In Michigan’s competitive fabrication and construction market, these errors mean missed deadlines, safety risks, and blown budgets.

The Guide

We Bring Shop-First Engineering to Michigan Projects. At Weldment Design, our professional engineers understand Michigan’s industries—automotive, heavy manufacturing, utilities, and construction. We don’t just design steel—we design for the shop floor. That means safer builds, fewer RFIs, and projects that run smoother.

OUR PROVEN PROCESS

1

Schedule a free project review.

Get an expert opinion on your project to identify opportunities and avoid costly mistakes.

2

Get a engineering package.

Stamped, buildable, precise, complying and thoroughly tailored to your project's specific requirements.

3

Deliver your project on time

Stay on track, on budget, and launch with confidence every single time. —with confidence.

Work with a Licensed Professional Engineer in Michigan

Michigan Engineering Services Provided by Our Professional Engineers

We provide licensed PE support across the state of Michigan for:

CAD design & drafting

Shop floor process drawings

Structural analysis & load path verification

Cost-reduction engineering reviews

Pressure vessel & tank design

Rigging, lifting, and shipping engineering

Constructability & safety reviews

#1 solution in the industry

FREQUENTLY ASKED QUESTIONS

Do I Need a Professional Engineer (PE) Here?

In many Michigan projects, especially government, utility, and safety-regulated work, a Professional Engineer’s stamp is required. Even when it isn’t, PE oversight helps you prevent rework, improve constructability, avoid permitting delays, and reduce compliance risk under OSHA, AISC, and state codes.

FREQUENTLY ASKED QUESTIONS

Which Cities Does Weldment Design Serve?

We serve projects across Michigan, covering all major metropolitan areas and industrial hubs. Wherever fabrication, construction, or heavy industrial work is happening in Michigan, Weldment Design supports your project.

We are licensed to cover engineering projects in all of the following major cities:

-Detroit

-Grand Rapids

-Warren city

-Sterling Heights

-Ann Arbor

-Lansing

-Dearborn

-Macomb

-Livonia

-Troy CIty

FREQUENTLY ASKED QUESTIONS

Why Michigan fabricators choose Weldment Design

Most delays happen because drawings can’t be built in the shop. We fix that.

Buildable designs crews can weld, bolt, and lift.

Safer projects with rigging and handling logic already built-in.

Fewer RFIs and delays because we think like the shop floor.

Predictable outcomes that save rework, overtime, and stress.

FREQUENTLY ASKED QUESTIONS

What Happens If I Don’t Use a Professional Engineer in Michigan?

Without engineering oversight, Michigan projects risk field rework, safety hazards, permitting delays, and unsafe workarounds. With Weldment Design, you get licensed PE oversight and engineering packages built for shops and job sites in Michigan.

MORE FREQUENTLY ASKED QUESTIONS

When does Michigan law require a PE stamp?

Whenever a design affects public safety—structures, pressure vessels, or systems installed permanently

Can I fabricate without a PE?

Yes, but permits or insurance may be denied if stamped drawings are missing.

What codes apply?

AISC, ASME, API-650, and Michigan Building Code reference PE oversight for critical components.

How long does PE approval take?

1–3 business days for standard packages; longer for field retrofits or design-build reviews.

Does a PE help with shop productivity?

Yes—reviewed designs reduce RFIs, rework, and field modifications.

What happens if a PE makes an error?

The PE carries professional liability insurance—protecting your firm from downstream claims.

Can I use out-of-state engineers?

Only if they’re licensed in Michigan or working under a Michigan-licensed PE.

What industries benefit most?

Steel fabrication, tank/vessel manufacturing, material handling, rigging, and modular construction.

Do stamped drawings expire?

No, but revisions require a new review and seal.

What if my client doesn’t ask for a PE?

Use one anyway—contractors who do often win bids based on compliance readiness.

Why Fabricators Switch to

Weldment Design

A clear comparison between typical engineering support experiences

and what weldment design delivers for heavy fabrication teams

Typical Engineering Support

Overworked internal teams cause delays

Drawings arrive late or missing critical details

Offshore designers don’t understand fabrication

Constant redlines and rework

High cost and long ramp-up for new hires

Communication is slow and disjointed

Weldment Design Support

Built-for-the-shop designs from industry pros

Precision output that gets it right the first time

Fabrication-ready drawings, fully detailed and accurate

Direct access to responsive, experienced engineers

On-demand bandwidth with senior US-based engineers

Flexible packages—no recruiting, no onboarding

Don't worry, we can help!

E X P E R T I S E

INDUSTRIES SERVED

Heavy Industrial Fabrication

Large weldments, shop-ready structural designs, and cost-reduction engineering.

Marine

Vessel components, tank design, rigging plans, and PE-stamped fabrication packages for shipyards.

Defense

Engineering support for secure, mission-critical fabrication and government projects.

Mining

Structural frames, lifting devices, and equipment support for mining and material handling sectors.

Energy

Pressure vessels, tanks, and structural systems supporting power, utility, and renewable projects.

ON-DEMAND FABRICATION

ENGINEERING SUPPORT

We offer tailored support plans to fit your current needs, flexible as those needs change, and grow as your demand grow.

Whether you’re just starting out, expanding your capabilities, or leading large complex projects, we have the fabrication engineering expertise you need.

FLEX DRAFT

CAD Technician

Focused on CAD and production support.

$135/hr

3D Modeling – Using SolidWorks or Inventor to model frames, plates, beams, gussets, etc.

2D Detailing for Shop Fabrication – Drawing production including weld symbols, BOMs, and material callouts.

Sheet Metal Flat Pattern Development – Unfolds, bend lines, and DXF outputs for laser/plasma/CNC.

Lofting and Nesting Support – Preparing layout drawings and optimizing cut plans for steel plate.

Drawing Cleanup and Standardization – Fixing legacy DWGs and ensuring compliance with customer standards.

Marking Plans and Weld Mapping – Visual guides for welders and fitters based on drawing sets.

DESIGN ASSIST

Design Engineer

Manufacturing engineer or experienced designer.

PE stamp not required.

$150/hr

Fixture & Tool Design – Designing reusable setups to improve fit-up and consistency.

Design for Manufacturability – Reducing cost with value engineered designs, creating procurement & fabrication efficiencies.

Tooling and Handling Equipment Design – Lifting beams, spreader beams and lift planning.

RFI and Submittal Package Support – Technical responses for contractor or fabricator questions.

Field Measurement and Retrofit Coordination – Working with on-site teams to verify existing conditions.

Shop Drawing Review & Coordination – Acting as a liaison between fabricator, detailer, and end client.

Connection Detailing per AISC or AWS Guidance – Baseplates, clip angles, tabs, and built-up sections.

DESIGN PRO

Professional Engineer

Fully licensed support for structural and

mechanical engineering.

$195/hr

Engineer-of Record Approved Drawings – Signed and stamped drawing sets for submittal and fabrication.

Structural Design and Analysis – Code compliant designs using state-of-the-art software and first principals.

Connection Design per AISC, RCSC, AWS, and Customer Specs – Custom moment, shear, and bracing checks.

Lifting & Handling Design – Safety Compliance & Certification Consultation. (OSHA, ASME, Below-the-Hook)

Full Design-Build Coordination – Managing both design intent and constructability from concept to final sign-off.

Project Management and Engineering Oversight – Scheduling, design reviews, and QA/QC on deliverables.

Your Time and Money Are Valuable.

Meeting project deadlines while ensuring quality work can feel impossible when resources are limited. That's where we come in. Our network of licensed engineers offers the support you need to keep your projects on track and within budget. With our expertise, you can trust in the structural integrity of your designs, allowing you to focus on what you do best — running your business.

We understand the challenges you face.

Partnership Success Stories

"It is very exciting to be growing in tandem with such a great company and leader!""

"Weldment Design and its team are a true partner for us at Capitol Engineering Co.! We have utilized the services he lists and several more - laser scan interpretation/design, weld engineering, etc. - for our heavy industrial fabrication business. We are even collaborating on business development opportunities.

- John Carney

"I highly recommend

Weldment Design"

"I've had the opportunity to work with Weldment Design and have consistently been impressed by their deep technical understanding of steel fabrication, welding, and design."

- Daniel Reed

"High Quality and

Detailed Work"

"Weldment Design provide high-quality, detailed work and his communication is always succinct and professional. I'd be happy to work with them in other venues!"

- Nick Paulick

Partnership Success Stories

"It is very exciting to be growing in tandem with such a great company and leader!""

"Weldment Design and its team are a true partner for us at Capitol Engineering Co.! We have utilized the services he lists and several more - laser scan interpretation/design, weld engineering, etc. - for our heavy industrial fabrication business. We are even collaborating on business development opportunities.

- John Carney

"I highly recommend

Weldment Design"

"I've had the opportunity to work with Weldment Design and have consistently been impressed by their deep technical understanding of steel fabrication, welding, and design."

- Daniel Reed

"High Quality and

Detailed Work"

"Weldment Design provide high-quality, detailed work and his communication is always succinct and professional. I'd be happy to work with them in other venues!"

- Nick Paulick

SOFTWARE ACCESS & EXPERTISE

Codeware focuses exclusively on providing software for the design and analysis of ASME vessels and exchangers. By combining engineering expertise, innovative software solutions and unmatched customer support, Codeware has established itself as the leading ASME Section VIII software provider. Our engineering software COMPRESS, INSPECT, and Shopfloor is used by 1,800+ companies in over 65 countries. Codeware was founded in 1983 in Ontario.

Design and engineer complex metal structures, weldments, assemblies, and custom equipment. It enables engineers to quickly create accurate structural models, generate detailed shop drawings, simulate load conditions, and streamline fabrication workflows. With built-in tools like Weldments, Sheet Metal, and Structural Simulation, SOLIDWORKS helps heavy fab teams reduce errors, accelerate production, and ensure fit, form, and function before cutting steel—saving time and material costs.

Design and engineer complex metal structures, weldments, assemblies, and custom equipment. It enables engineers to quickly create accurate structural models, generate detailed shop drawings, simulate load conditions, and streamline fabrication workflows. With built-in tools like Weldments, Sheet Metal, and Structural Simulation, SOLIDWORKS helps heavy fab teams reduce errors, accelerate production, and ensure fit, form, and function before cutting steel—saving time and material costs.

PRIME & SUB GOVERNMENT CONTRACTORS

STATE & LOCAL GOV.

INDUSTRY STANDARDS

SOFTWARE ACCESS & EXPERTISE

Codeware focuses exclusively on providing software for the design and analysis of ASME vessels and exchangers. By combining engineering expertise, innovative software solutions and unmatched customer support, Codeware has established itself as the leading ASME Section VIII software provider. Our engineering software COMPRESS, INSPECT, and Shopfloor is used by 1,800+ companies in over 65 countries. Codeware was founded in 1983 in Ontario.

Design and engineer complex metal structures, weldments, assemblies, and custom equipment. It enables engineers to quickly create accurate structural models, generate detailed shop drawings, simulate load conditions, and streamline fabrication workflows. With built-in tools like Weldments, Sheet Metal, and Structural Simulation, SOLIDWORKS helps heavy fab teams reduce errors, accelerate production, and ensure fit, form, and function before cutting steel—saving time and material costs.

Design and engineer complex metal structures, weldments, assemblies, and custom equipment. It enables engineers to quickly create accurate structural models, generate detailed shop drawings, simulate load conditions, and streamline fabrication workflows. With built-in tools like Weldments, Sheet Metal, and Structural Simulation, SOLIDWORKS helps heavy fab teams reduce errors, accelerate production, and ensure fit, form, and function before cutting steel—saving time and material costs.

PRIME & SUB GOVERNMENT CONTRACTORS

STATE & LOCAL GOV.

INDUSTRY STANDARDS

SOFTWARE ACCESS & EXPERTISE

Codeware focuses exclusively on providing software for the design and analysis of ASME vessels and exchangers. By combining engineering expertise, innovative software solutions and unmatched customer support, Codeware has established itself as the leading ASME Section VIII software provider. Our engineering software COMPRESS, INSPECT, and Shopfloor is used by 1,800+ companies in over 65 countries. Codeware was founded in 1983 in Ontario.

Design and engineer complex metal structures, weldments, assemblies, and custom equipment. It enables engineers to quickly create accurate structural models, generate detailed shop drawings, simulate load conditions, and streamline fabrication workflows. With built-in tools like Weldments, Sheet Metal, and Structural Simulation, SOLIDWORKS helps heavy fab teams reduce errors, accelerate production, and ensure fit, form, and function before cutting steel—saving time and material costs.

Design and engineer complex metal structures, weldments, assemblies, and custom equipment. It enables engineers to quickly create accurate structural models, generate detailed shop drawings, simulate load conditions, and streamline fabrication workflows. With built-in tools like Weldments, Sheet Metal, and Structural Simulation, SOLIDWORKS helps heavy fab teams reduce errors, accelerate production, and ensure fit, form, and function before cutting steel—saving time and material costs.

PRIME & SUB GOVERNMENT CONTRACTORS

INDUSTRY STANDARDS

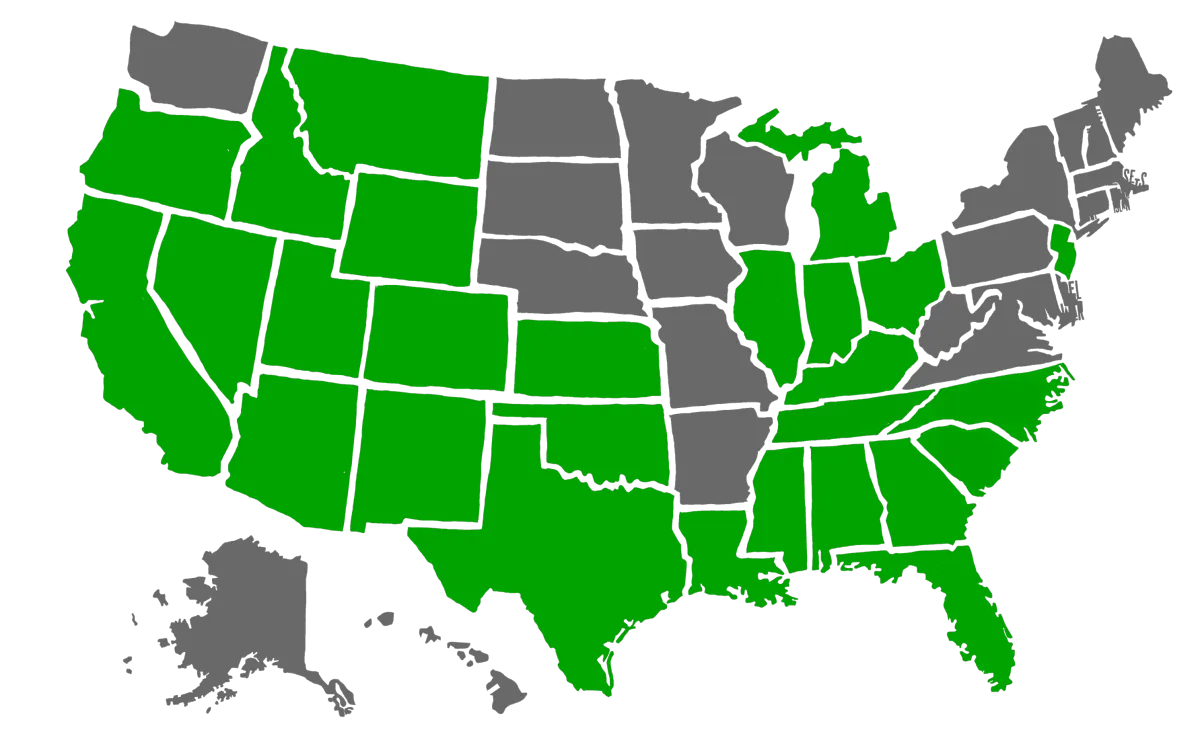

Licensed

Professional Engineer

in the Following States.

STATES

ALABAMA

ARIZONA

CALIFORNIA

COLORADO

FLORIDA

GEORGIA

IDAHO

ILLINOIS

INDIANA

KANSAS

KENTUCKY

LOUISIANA

MICHIGAN

MISSISSIPPI

MONTANA

NEVADA

NEW MEXICO

NEW JERSEY

NORTH CAROLINA

OHIO

OREGON

OKLAHOMA

SOUTH CAROLINA

TENNESSEE

TEXAS

UTAH

WYOMING

Avoid common design mistakes!

5 Common Mistakes in heavy fabrication design and How to Avoid Them

Each mistake increases the risk of design failure or potentially cost your team to be past due & over budget.

dOWNLOAD OUR FREE GUIDE

Weldment Design provides professional engineering services in Michigan, covering all major metro areas and industrial hubs. Services include CAD design, drafting, structural analysis, shop process drawings, cost reduction, constructability reviews, rigging engineering, and PE-stamped pressure vessel and tank design.